When you purchase through links in our articles, Future and its syndication partners may earn a commission.

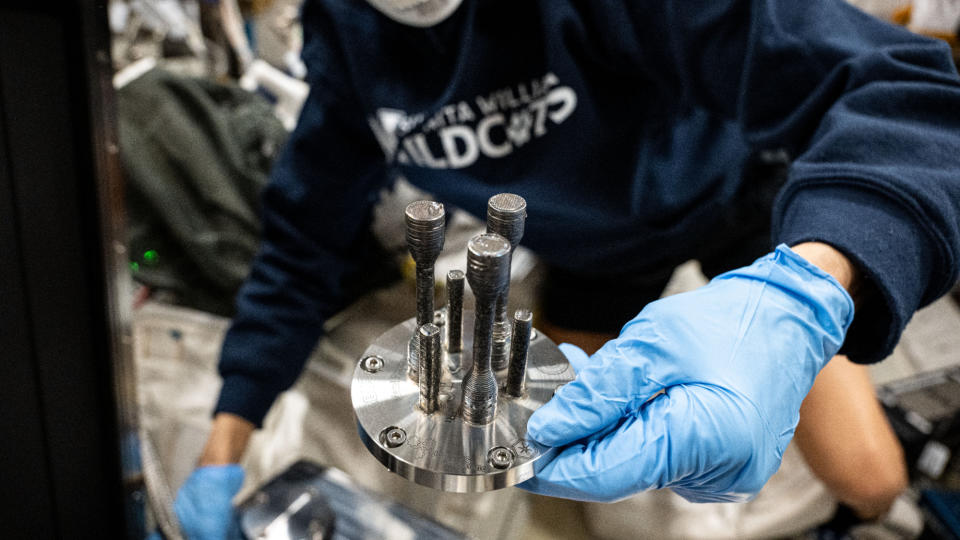

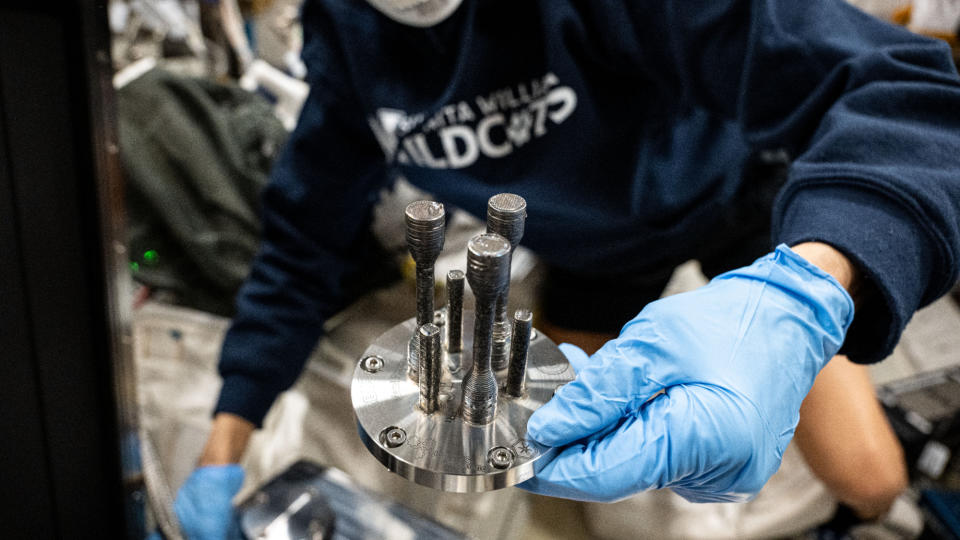

ESA scientists have successfully demonstrated 3D printing of a metal part in space for the first time.

3D printing in space is challenging because many methods rely on Gravity to position materials during the printing process. This is because the production of metal structures often uses molten metal as part of the filament or printable medium. In Spaceits behavior can be unpredictable, resulting in objects of inferior quality because the filament could shift or become misplaced due to a lack of gravitational forces.

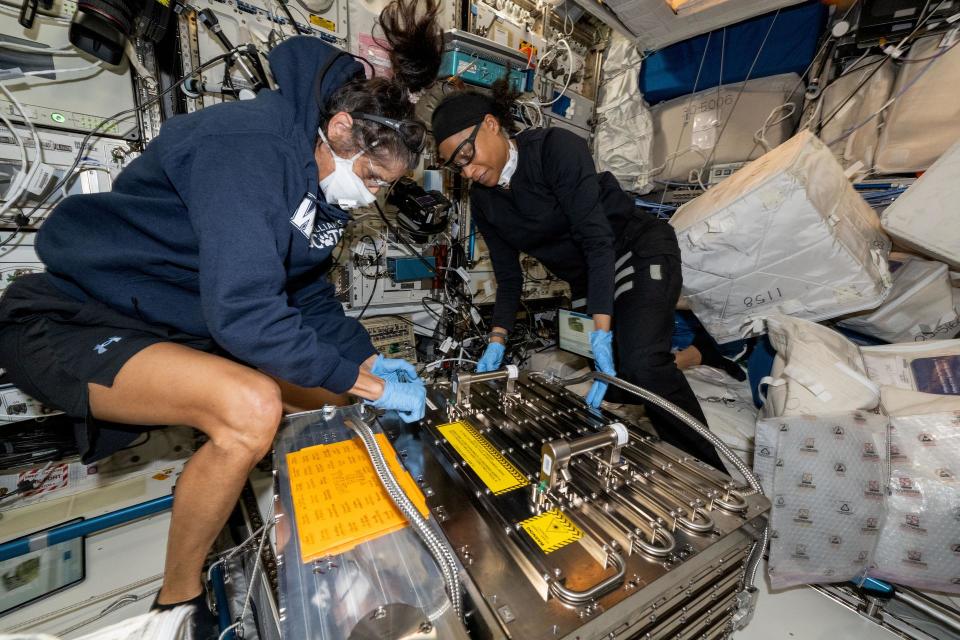

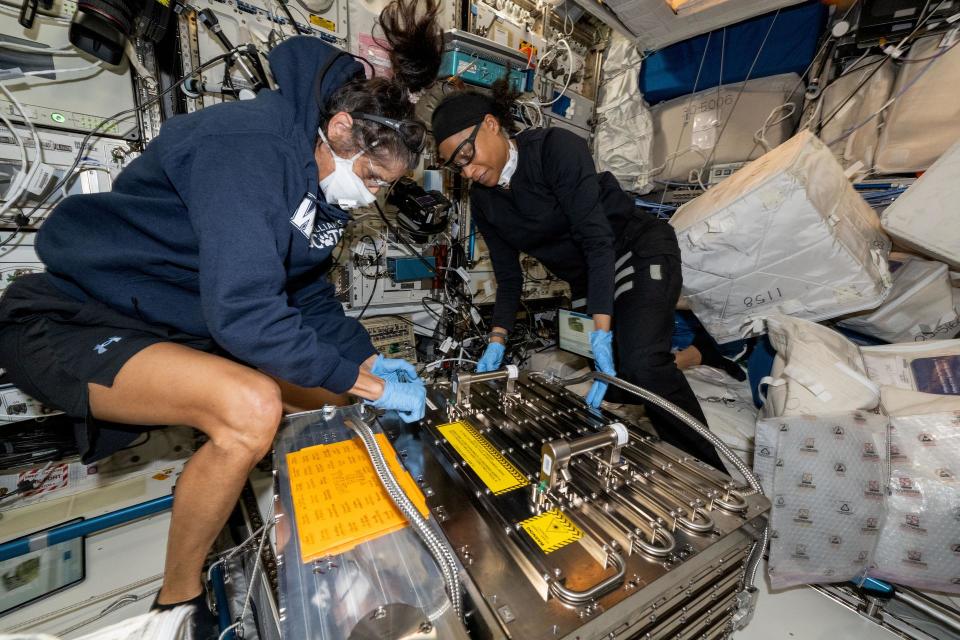

The scientists therefore had to adapt to working under these difficult conditions, and the International Space Station provided the perfect environment. ESA’s metal 3D printer uses a stainless steel wire melted by a powerful laser reaching 1200 °C (2,192 °F) to create its molten metal filament, which is deposited layer by layer to build up a desired shape.

Through careful testing over several months, the team finally managed to adapt the printer to the microgravity environment and produce the first metal part in space in August 2024. The team plans to print two more objects, then all three will be returned Earth for quality analysis and future planning.

Related: Future lunar astronauts could produce their supplies using 3D printing of lunar minerals

“By printing the first metal 3D mold in space, ESA’s exploration teams have reached an important milestone in building in-orbit manufacturing capabilities. This achievement, made possible by an international and multidisciplinary team, paves the way for long-distance and long-duration missions where on-demand manufacturing of spare parts, building components and tools will be crucial,” said Daniel Neuenschwander, ESA’s Director of Human and Robotic Exploration, in a statement.

This groundbreaking technology is being used more and more frequently on Earth and is revolutionising areas such as medicine, fashion, art, construction, food production and manufacturing. In space, on long-term missions to the moon and possibly Mars In order for astronauts to take shape, they need a way to independently repair or manufacture tools or parts for machines or structures that would be difficult to transport due to the limited capacity of a spacecraft.

As technology advances, it may one day be possible to print new tissues or organs, enabling long-term space exploration. However, it will be decades before this becomes a reality.

Related Posts:

— 3D-printed hearts on the ISS could help astronauts travel into space

— A BFF in space! Bioprinter will 3D print human tissue on the space station

— The best space-themed 3D prints: Recreate iconic spaceships and objects

3D printers in space are nothing new, with microgravity providing an interesting environment for scientists to conduct experiments, develop better 3D printing materials or create structures that would be difficult to manufacture on Earth. But what’s significant about ESA’s recent announcement is that this is the first time a 3D printer has successfully produced a metal part.

This capability represents an important milestone, as until this point, metal components for space missions had to be manufactured on Earth and transported into orbit – a costly and complex part of any mission.